In the dynamic landscape of industrial manufacturing and product development, strategic foresight is paramount. For entities operating within or targeting the European market, adherence to evolving regulatory frameworks, particularly those pertaining to environmental sustainability, constitutes a critical business imperative. The emergent emphasis on European Regulations for Sustainable Packaging represents not merely a compliance requirement, but a significant strategic opportunity for market differentiation and competitive advantage.

This comprehensive overview will delineate the intricacies of the new EU Packaging and Packaging Waste Regulation (PPWR), providing essential insights for manufacturers and industrial enterprises seeking to navigate this transformative legislative environment effectively.

The Paradigm Shift: Understanding the PPWR Framework

The PPWR signifies a pivotal legislative advancement within the European Union, engineered to foster a more circular economy for packaging materials. Unlike previous directives, the PPWR is a directly applicable regulation, thereby ensuring harmonized implementation across all EU Member States. This uniformity is a distinct advantage, streamlining compliance efforts for businesses operating across diverse national jurisdictions.

The Regulation officially entered into force in February 2025. While certain provisions had immediate applicability, the majority of its key requirements, including stringent recyclability and reuse targets, are scheduled to commence enforcement from August 12, 2026. Subsequent staggered targets are stipulated for 2030, 2035, and 2040, indicating a long-term commitment to a sustainable packaging ecosystem.

PPWR Implementation Timeline: Key Milestones

|

Date |

Key Provisions Effective |

|

February 2025 |

PPWR officially enters into force. |

|

August 12, 2026 |

General application date for most PPWR provisions, including initial requirements for substances in food contact packaging and the foundation for “design for recycling.” EPR fees to be paid by parties placing their packaging products on the market, will be based on recyclability performance grades. |

|

January 1, 2030 |

All packaging (with limited exceptions) must be “recyclable by design.” Bans on specific single-use plastic packaging formats take effect. Minimum recycled content targets for plastic packaging apply (e.g., 30% for PET beverage bottles). Packaging minimization becomes mandatory, with empty space in certain packaging designs not exceeding 50%. First reuse targets apply (e.g., 40% of transport/sales packaging volume for re-use systems). |

|

January 1, 2035 |

All packaging must be “recyclable at scale.” Higher reuse targets apply. |

|

January 1, 2040 |

Further increased waste reduction targets (-15% vs. 2018 levels). Higher recycled content targets for plastic packaging (e.g., 65% for non-food plastic packaging). Even more ambitious reuse targets (e.g., 70% of transport/sales packaging volume). |

Strategic Implications for Businesses

The PPWR necessitates a proactive and comprehensive reassessment of current packaging strategies for all businesses involved in placing packaged products on the EU market. The Regulation’s impact extends across various facets of product development and supply chain management:

-

Design for Recycling: A fundamental shift towards designing packaging that is inherently compatible with existing recycling infrastructure.

-

Minimum Recycled Content: Adherence to mandated percentages of recycled material, particularly within plastic packaging.

-

Reuse Targets: Integration of scalable reuse and refill systems where applicable.

-

Harmonized Labeling: Implementation of standardized, EU-wide labeling to facilitate correct material identification and disposal.

-

Waste Reduction: Active minimization of packaging weight, volume, and void space.

Non-compliance with these stringent requirements may result in significant penalties and restrictions on market access, underscoring the urgency of strategic adaptation.

Core Objectives of the PPWR

The overarching objectives of the PPWR align with the broader goals of the EU Green Deal and the Circular Economy Action Plan, aiming to transition towards a climate-neutral and resource-efficient economy. The primary goals include:

-

Waste Reduction: Achieve ambitious targets for reducing packaging waste generation per capita: -5% by 2030, -10% by 2035, and -15% by 2040, relative to 2018 levels. This emphasis extends beyond recycling to prioritize waste prevention.

-

Enhanced Recyclability: Ensure that all packaging placed on the market by 2030 is designed for recyclability and by 2035 is recyclable at scale.

-

Promotion of Reuse and Refill Systems: Significantly increase the adoption of reusable packaging solutions across various sectors.

-

Increased Recycled Content: Mandate minimum recycled content in new plastic packaging, fostering demand for secondary raw materials.

-

Market Harmonization: Establish a unified regulatory framework across EU Member States to reduce complexity and foster a seamless internal market for packaging and packaging materials.

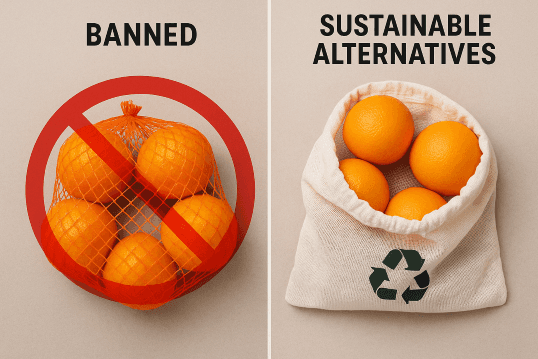

Restrictions on Single-Use Packaging

Building upon the foundations laid by the Single-Use Plastics Directive (SUPD) updates, the PPWR introduces further prohibitions on specific single-use plastic packaging formats. Commencing January 1, 2030, a range of single-use plastic packaging items will be banned, including:

-

Packaging for unprocessed fresh fruits and vegetables.

-

Specific food and beverage containers used within the Horeca sector (hotels, restaurants, cafes).

-

Miniature single-serve toiletry packaging in accommodation facilities.

-

Very lightweight plastic carrier bags.

This regulatory evolution necessitates a proactive transition away from these packaging types, underscoring the market demand for sustainable alternatives.

Advancing Circularity: Recycling and Recycled Content Mandates

The PPWR sets rigorous EU packaging recycling targets 2030 and beyond, transforming the landscape of packaging material utilization.

-

Recyclable by Design (by 2030): All packaging must be designed to be theoretically compatible with existing recycling processes. This emphasizes material selection and structural design that facilitates efficient separation and recovery.

-

Recyclable at Scale (by 2035): Packaging must not only be designed for recyclability but also be widely collected and effectively recycled in practice across a significant portion of the EU. This shifts the focus from theoretical recyclability to verifiable, practical recycling outcomes.

Furthermore, the PPWR mandates specific recycled content mandates EU packaging, particularly for plastic materials, to stimulate the circular economy for plastics.

Minimum Recycled Content in Plastic Packaging

|

Plastic Packaging Type/Application |

Minimum Recycled Content by 2030 |

Minimum Recycled Content by 2040 |

|

PET Beverage Bottles |

30% |

65% |

|

Other Plastic Packaging (excluding specific contact-sensitive) |

35% |

65% |

|

Contact-Sensitive Plastic Packaging (e.g., for food, where applicable) |

10% (from 2030 if predominantly plastic) |

Higher targets to be defined |

These targets compel manufacturers to integrate higher proportions of Post-Consumer Recycled (PCR) materials into their packaging, driving demand for recycled plastics.

Strengthening Extended Producer Responsibility (EPR)

The Extended Producer Responsibility (EPR) EU framework is significantly reinforced under the PPWR, shifting greater financial and operational responsibility for packaging waste management to producers.

A key development is the mandatory eco-modulation of EPR fees. This mechanism links the fees producers pay into national EPR schemes directly to the recyclability performance and recycled content of their packaging. Packaging that is easily recyclable or contains a high percentage of recycled material will incur lower fees, while packaging that is problematic or difficult to recycle will face higher charges. This financial incentive directly encourages EU packaging design for recycling and sustainable material choices.

Harmonized Labeling Requirements

To streamline waste sorting and enhance recycling rates across the Union, the PPWR introduces new, harmonized labeling requirements for packaging.

-

Standardized Symbols: Packaging must feature consistent, EU-wide symbols indicating material composition and proper disposal instructions. This uniformity aims to reduce consumer confusion and improve sorting accuracy.

-

Digital Information via QR Codes: The increasing adoption of QR codes on packaging will provide consumers with detailed information regarding reusability, material composition, and precise guidance on collection points.

Addressing Over-Packaging and Void Space

The PPWR directly confronts the issue of excessive packaging, setting explicit limitations to minimize material consumption and waste generation.

-

The Regulation prohibits packaging that is demonstrably larger or heavier than required for product protection and functionality.

-

Specifically, from January 1, 2030, the percentage of empty space in certain packaging categories (e.g., transport packaging, e-commerce packaging, individual B2B/B2C shipments) may not exceed 50%.

This requirement has substantial implications, particularly for the e-commerce sector, driving demand for optimized packaging designs and efficient void fill solutions. It directly contributes to overall packaging waste reduction Europe.

Defining Recyclability: Design vs. Scale

The PPWR distinguishes between two critical aspects of recyclability, providing a comprehensive framework for compliance:

-

“Recyclable by Design” (by 2030): This criterion assesses whether packaging materials and structural elements are inherently compatible with existing recycling technologies and processes. It focuses on the theoretical capability for recycling based on material science and manufacturing.

-

“Recyclable at Scale” (by 2035): This more stringent criterion evaluates whether packaging is not only designed for recycling but is also widely collected, sorted, and effectively recycled in practice across a significant portion of the EU. This considers the practical availability and efficiency of recycling infrastructure.

This two-tiered approach aims to ensure that sustainability claims are substantiated by both technical design and real-world recycling outcomes.

Specific Considerations for Paper-Based Packaging

As industries seek alternatives to conventional plastics, paper-based packaging is often positioned as a sustainable solution. However, under the PPWR, even these materials are subject to rigorous scrutiny.

-

Recyclability Criteria for Barriers: While paper-based packaging EU compliance is generally favorable, the presence of barrier coatings (e.g., for moisture, grease, or oxygen) and composite structures must not impede the recyclability of the paper fiber. Innovations in dispersion coatings or easily separable layers are critical to ensure that paper-based solutions remain recyclable in conventional paper streams.

-

Compostability Standards: For paper-based packaging marketed as compostable, adherence to harmonized European standards, such as EN 13432 for industrial composting, remains essential. This ensures that such packaging genuinely biodegrades within specified timeframes and conditions.

-

“Recyclable at Scale” for Paper: Even pure paper packaging must be effectively collected and processed by widespread recycling infrastructure to meet the “recyclable at scale” criterion. This necessitates ongoing investment in and optimization of paper recycling facilities across the EU.

Navigating Compliance: A Strategic Imperative

Achieving compliance with these multifaceted regulations requires a structured and proactive approach. Industrial companies and manufacturers must implement robust strategies to manage their packaging portfolios effectively. Key steps include:

-

Comprehensive Packaging Audit: Conduct a thorough assessment of existing packaging materials, designs, and end-of-life pathways to identify areas of non-compliance or improvement.

-

Strategic Redesign: Prioritize EU packaging design for recycling from the outset. Consider mono-materials (packaging made from a single material type), easily separable components, and the inclusion of recycled content.

-

Material Innovation: Invest in or explore new sustainable materials, particularly advancements in paper-based solutions and recyclable barrier technologies that meet EU standards.

-

EPR Scheme Engagement: Ensure registration and full participation in all relevant national EPR schemes within EU Member States where products are placed on the market. Leverage eco-modulation of EPR fees to incentivize sustainable design.

-

Supply Chain Collaboration: Work closely with your suppliers to verify material compliance, including adherence to PFAS restrictions food packaging EU and other substance limitations.

-

Labeling Implementation: Develop and deploy compliant, harmonized labeling systems across all packaging to aid consumer sorting and meet regulatory requirements.

-

Expert Consultation: Given the complexity and evolving nature of these regulations, engaging with specialized consultants is crucial.

The Future Landscape of EU Packaging Legislation

The PPWR serves as a foundational element within Europe’s broader sustainability agenda. The future of packaging legislation EU will undoubtedly continue to push towards greater circularity, amplified reuse, and continuous material innovation. Furthermore, the forthcoming Green Claims Directive packaging impact will require verifiable substantiation for any environmental claims made about packaging, increasing the demand for transparency and robust data.

For industrial enterprises, this regulatory trajectory represents not a mere challenge but a profound opportunity. Companies that proactively integrate these sustainability principles into their core business strategies, from product design to end-of-life management, will secure a decisive competitive advantage in the European market.

Leveraging Engineering Simulation for Compliance and Innovation

Navigating the complexities of the PPWR, particularly the mandates for “recyclable by design” and “recyclable at scale,” necessitates precision and predictive capabilities. This is where advanced engineering simulation consulting becomes an indispensable tool for manufacturers.

Consider the intricate requirements of redesigning packaging to meet new material content or structural mandates. How can a manufacturer ensure a newly designed paper-based container, for instance, will maintain structural integrity throughout the supply chain, or that its innovative barrier layer will not compromise its recyclability, before committing to costly physical prototypes and mass production?

The answer lies in simulation.

Companies like MSTECH offer specialized expertise and advanced computational tools to virtually test and optimize packaging designs. Their services, including Structural Simulation and Composite Simulation, enable businesses to:

-

Validate Material Performance: Simulate how novel materials, such as advanced paper-based substrates (leveraging Paper material Simulation) or biodegradable coatings, perform under various environmental conditions, mechanical stresses, and temperature fluctuations. This is particularly vital for ensuring paper-based packaging EU compliance.

-

Optimize Design for Recyclability: Through detailed analysis, MSTECH can assess the recyclability of new packaging designs, modeling how different layers or adhesives interact within recycling streams. This direct insight supports achieving the “recyclable by design” criterion.

-

Enhance Resource Efficiency: Through precise simulations, you can optimize packaging dimensions and material thickness. This contributes to significant packaging waste reduction Europe by minimizing excess material and void space, in line with the PPWR’s 50% limit.

-

Accelerate Development Cycles: Virtual prototyping through simulation significantly reduces the need for multiple physical prototypes, compressing development timelines and enabling faster market entry for compliant products.

-

Mitigate Compliance Risks: Identify potential non-compliance issues, design flaws, or material incompatibilities early in the development process, preventing costly rework and potential market restrictions.

-

Assess Durability: Utilize Fatigue Analysis to evaluate the long-term durability of new packaging materials under repetitive loading, crucial for both single-use and reusable designs.

-

Evaluate Environmental Footprint: Employ Life Cycle Assessment (LCA) to measure the environmental impact of your product and packaging from cradle to grave, ensuring a holistic approach to sustainability.

-

Optimize Material Behavior: With services like UMAT Material Modeling, MSTECH can develop customized subroutines to accurately capture complex material behaviors for precise simulation.

-

Improve Energy Efficiency: Explore Energy Optimization for your packaging processes and designs, aligning with broader sustainability goals.

This strategic partnership with experts like MSTECH empowers manufacturers to not only comply with EU sustainable packaging law but also to innovate efficiently and effectively. For further information on leveraging simulation to meet your sustainable packaging objectives, explore the comprehensive services offered by MSTECH at mstech.se/our-services/.

Conclusion: A Proactive Approach to Sustainable Packaging Leadership

The European Regulations for Sustainable Packaging, spearheaded by the impactful PPWR, signify a fundamental shift in how products are brought to market within the EU. This legislative evolution compels industrial companies and manufacturers to re-evaluate their entire packaging lifecycle, from material selection and design to end-of-life management.

While the regulatory landscape presents significant challenges, it simultaneously offers unparalleled opportunities for market leadership. Organizations that proactively integrate these sustainability principles into their core operational strategies, and leverage advanced tools like engineering simulation, will be exceptionally well-positioned. They will not only ensure compliance but also enhance brand reputation, achieve operational efficiencies, and secure enduring market access in an increasingly environmentally conscious European economy.

The imperative is clear: strategic adaptation and technological adoption are no longer optional. They are critical determinants of future success in the European industrial landscape.

How is your organization preparing for the comprehensive requirements of the PPWR? Contact MSTECH Sweden to help you shaping your plans.

Comments

Tap into unlimited earning potential—become our affiliate partner!

Become our affiliate and watch your wallet grow—apply now!